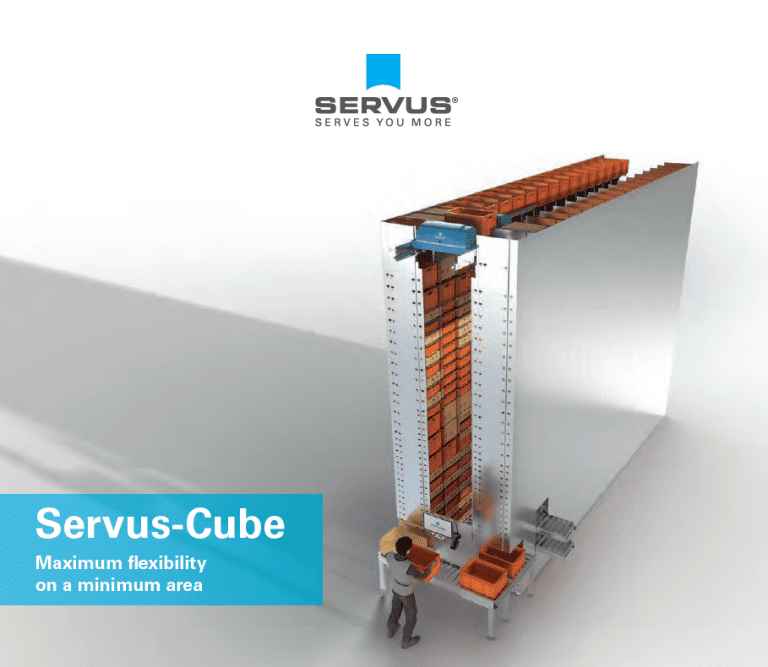

Servus-Cube

The digital storage system for beginners and professionals

By loading the video, you agree to YouTube's privacy policy.

Learn more

Fully automated at all levels – future-proof in every application

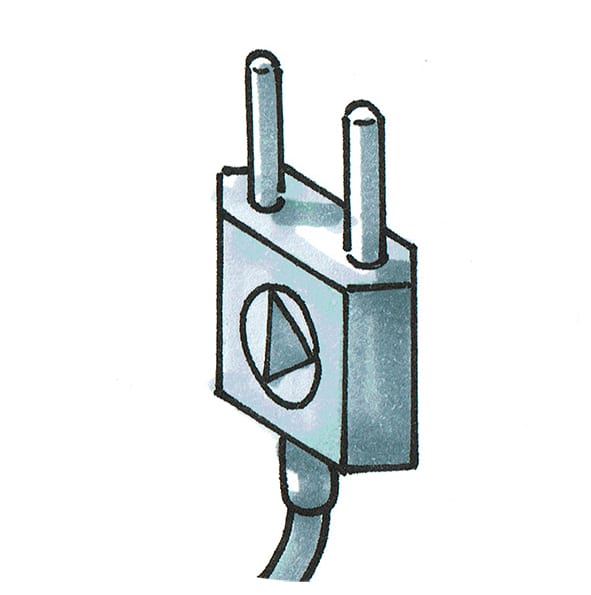

Whether trade, construction, or industry: as a simple Plug-and-Play solution, the flexible Servus-Cube is the perfect introduction into automated storage – and the ideal addition to existing intralogistics systems.

By loading the video, you agree to YouTube's privacy policy.

Learn more

More flexibility, new opportunities, higher added value

Maximum efficiency in warehouse and production. From incoming to outgoing goods.

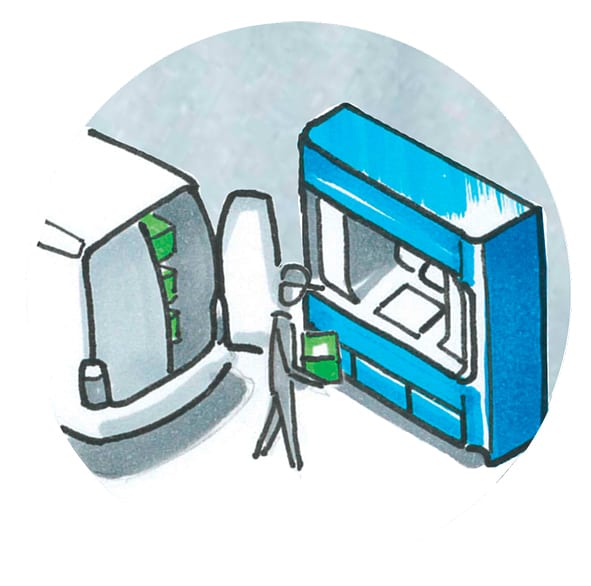

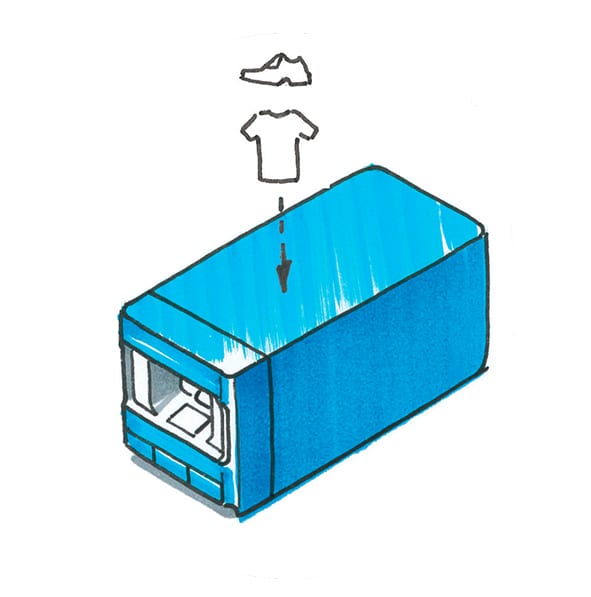

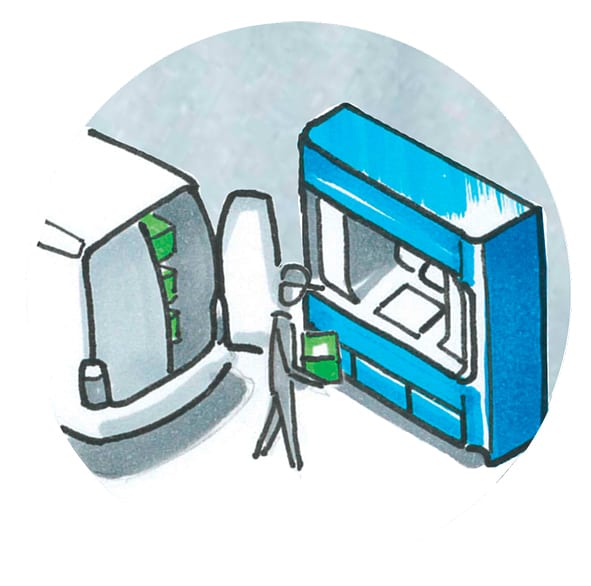

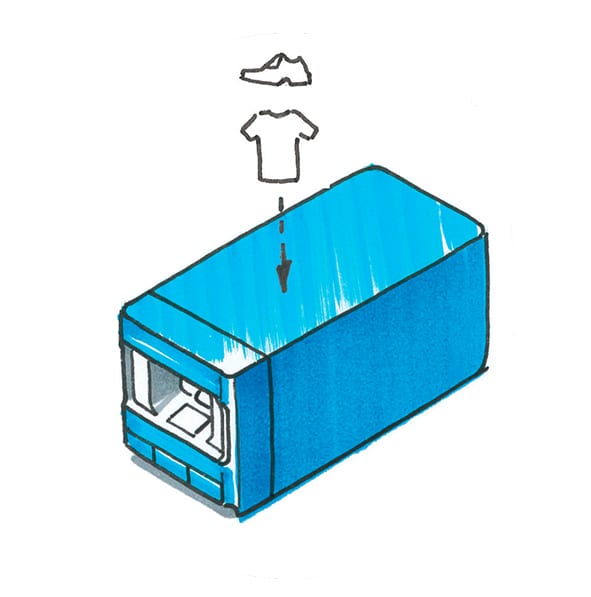

The Servus-Cube can be used flexibly: in warehouse and production logistics, as a mobile, automated warehouse on-site, and for digital incoming and outgoing goods. The Servus-Cube can even be ideally used as an innovative 24/7 delivery and collection station.

More flexibility, new opportunities, higher added value

Maximum efficiency in warehouse and production. From incoming to outgoing goods.

The Servus-Cube can be used flexibly: in warehouse and production logistics, as a mobile, automated warehouse on-site, and as a digital incoming and outgoing goods. The Servus-Cube can even be ideally used as an innovative 24/7 delivery and collection station.

One storage for many applications

The Servus-Cube creates the prerequisites for you to extend and optimise the value chain together with your suppliers and partners. This is because the automation of processes also creates more efficiency beyond production. Thanks to its maximum flexibility, the Servus-Cube can be easily adapted to individual customer needs and increasing requirements. This way, you are guaranteed to steer your logistics safely into the future."

Founder, Owner and CEO

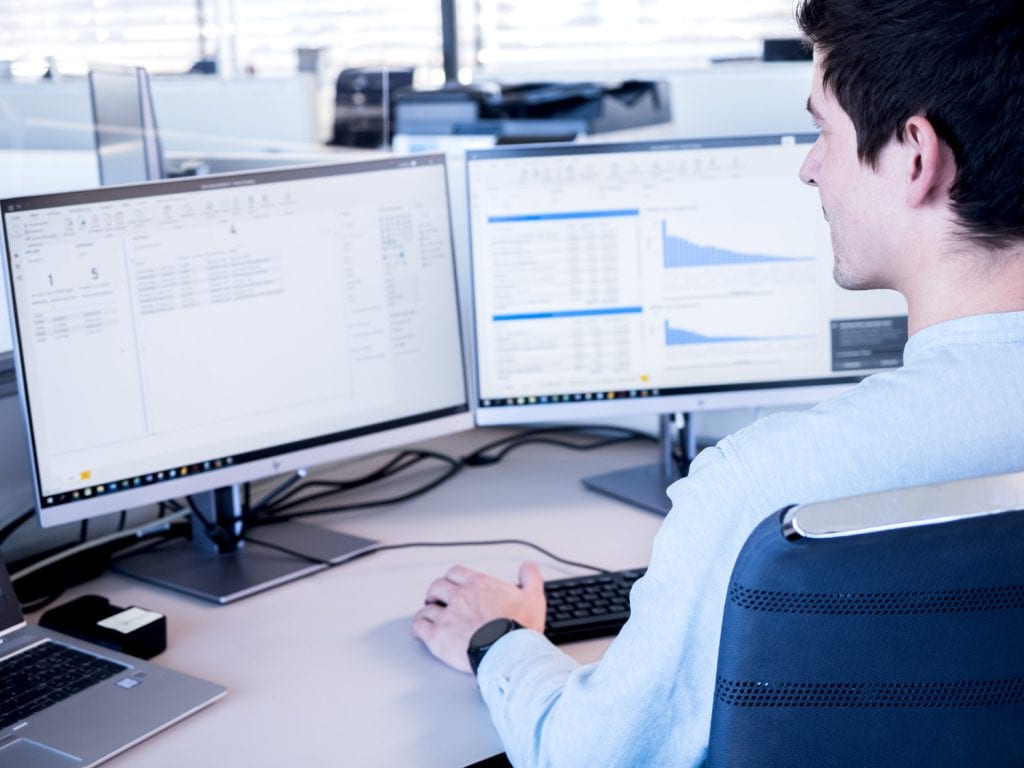

CubeOn – the intuitive software solution

Whether hardware or software – the aspiration is always: highest quality.

CubeOn is the name of the standard software for warehouse management, control, and operation of the Servus-Cube. Just as with the hardware, the aspiration is: simple, fast, and flexibly adaptable – also for future requirements.

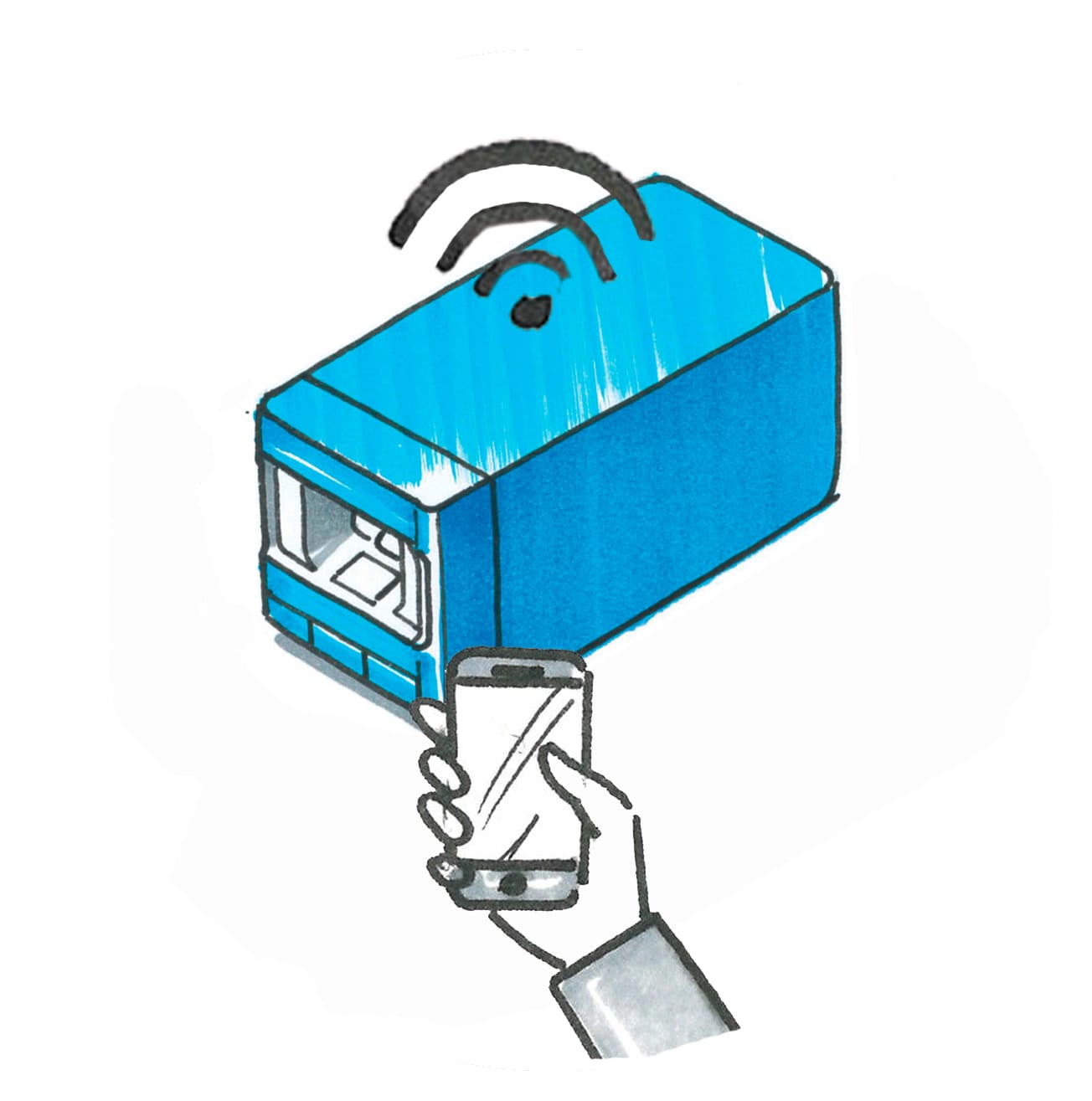

The user interface visualises system status, stock information, transport orders, and other important key figures, as well as plant monitoring and process control. The modern interfaces can be accessed on the computer, tablet and smartphone. This allows you to optimally plan your logistics strategies and efficiently execute them at the same time. The basic functions can be adapted and expanded to your individual needs.

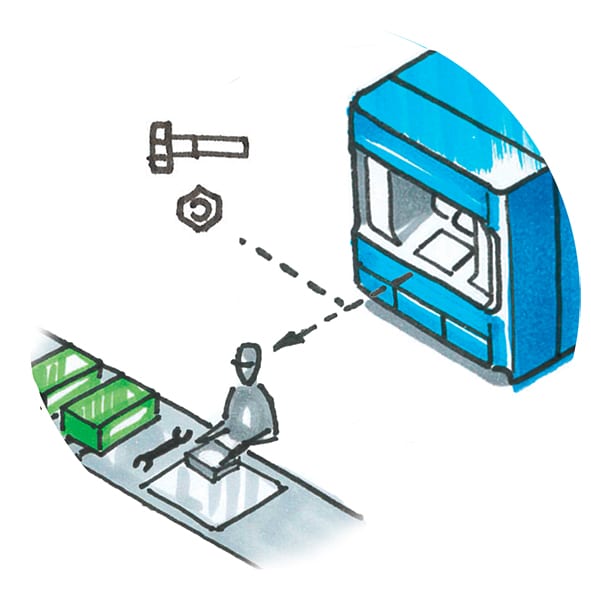

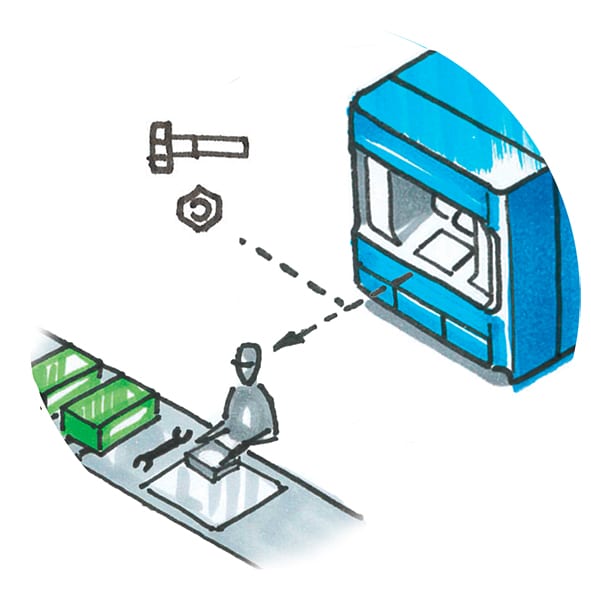

Thanks to its direct and thus extremely fast access time, the Servus-Cube meets the requirements of maximum flexible intralogistics. The system is additionally supported by the features of the CubeOn software, which can also be used on mobile devices. With CubeOn, the required material is already requested in advance and is available in a few seconds - without waiting, without searching. Faster is better. Today and tomorrow.

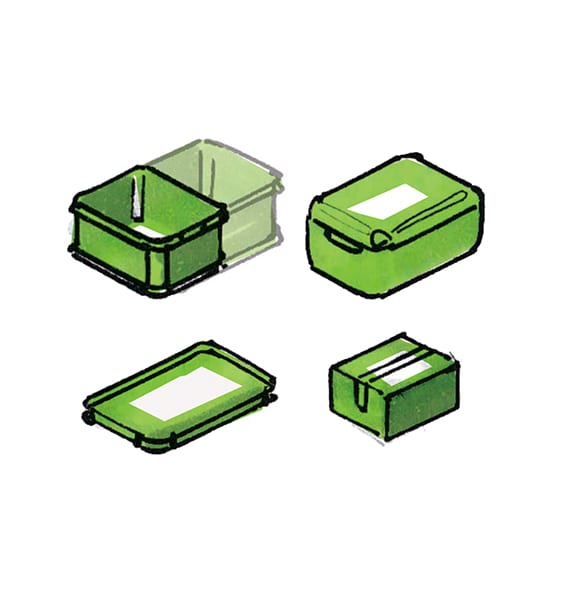

The Servus-Cube has no restrictions or dependencies on standardised boxes or loading equipment - it can cope with all containers and surface conditions such as cardboard boxes or workpiece carriers. The universal, material-friendly load handling device can handle containers as well as trays, cartons, polystyrene, or workpiece carriers. This makes the Servus-Cube unique – and you flexible for the future.

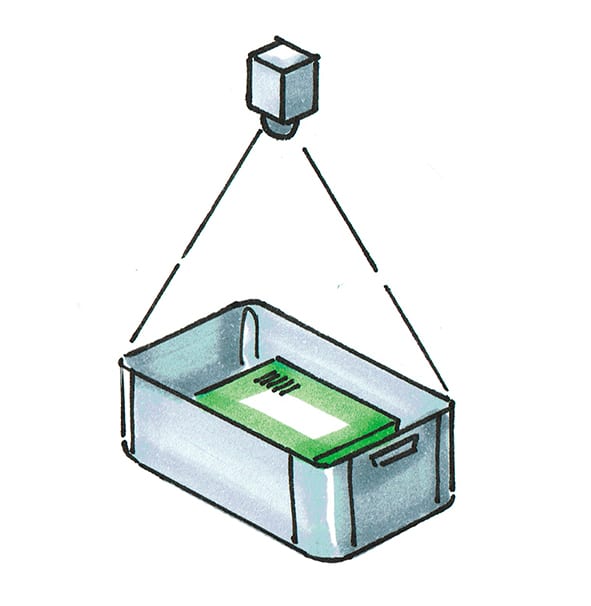

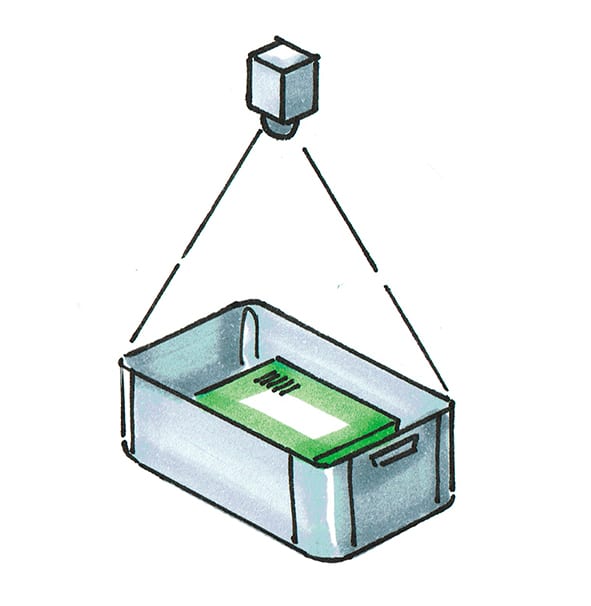

The newly developed Servus Checkpoint makes storage and retrieval 100% process reliable. Authorised employees, suppliers, and customers can be integrated into fully automated incoming and outgoing goods processes. All data is available in real time directly after storage or retrieval via intelligent camera monitoring and optional weight measurement. The result: maximum flexibility, faster processing times, and lower logistics costs.

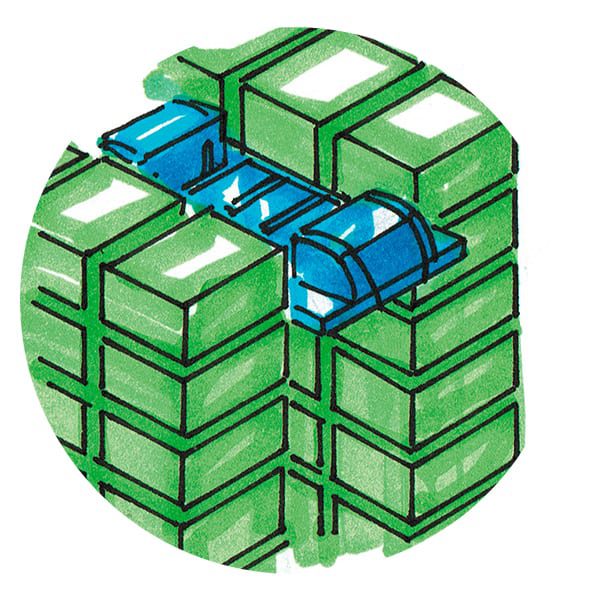

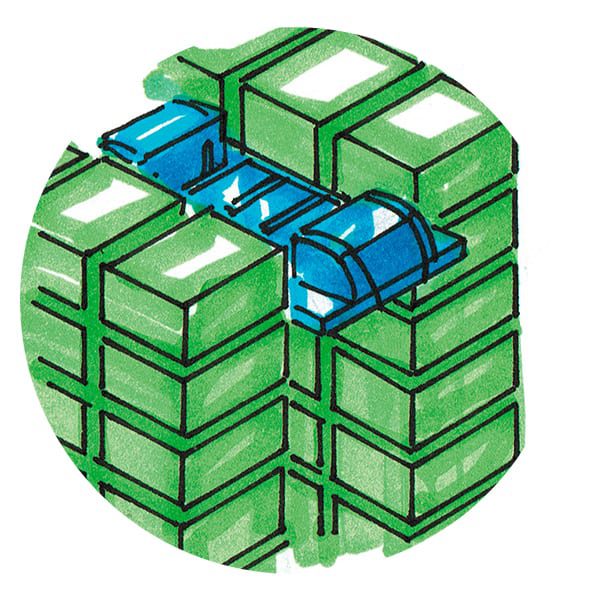

The Servus-Cube offers optimum space efficiency in warehouses and production facilities thanks to its unique storage density with direct access. Thanks to the innovative lifting technology of the Servus-Lifter, it only needs one guide rail and containers can be lined up very closely together. This results in a tidy and digital warehouse that saves space and minimises the waste of valuable floor space. The Servus-Cube can be extended to any length and up to almost six metres in height. This makes it a suitable storage system in the range of 100 to 100,000 storage locations.

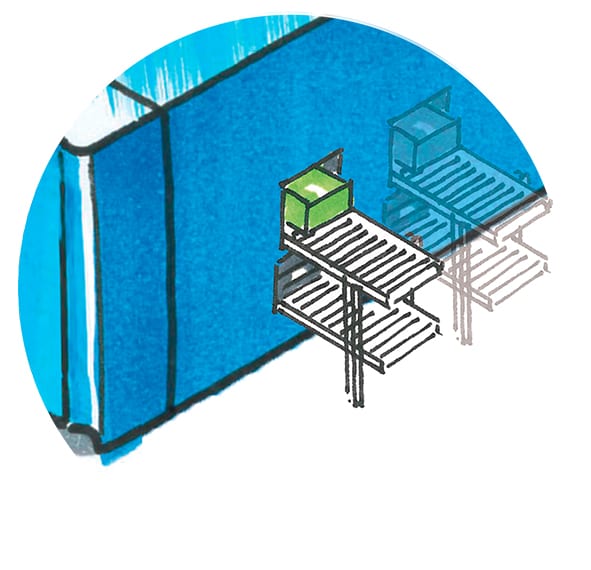

The loading and onward transport of the Servus-Cube can be individually adapted. With this versatility, the Servus-Cube can be flexibly integrated into all internal logistics processes: Both manual storage and retrieval stations, the collection of goods via the Servus Checkpoint, and automated variants with the Servus transport robot, the Servus Lifter, or an AGV are possible. This way you remain flexible for the future.

Smart Features

Plug-and-Play

Universally applicable

Maximum speed 3 seconds

A new world record!

The merging of warehouse and production

Modularly expandable

100% process reliable

User friendly and innovative

Flexible for every connection

In service around the clock

The all-rounder for every use

At the right place, at the right time

Plug-and-Play

The perfect introduction to automation Expandable and integrable at any time

Universally applicable

The universal and material-friendly load handling device stores containers, trays, cartons, polystyrene, workpiece carriers, etc.

Maximum speed 3 seconds

Pre-storage of goods through appropriate input and output stations. Optimally combined with the innovative Servus app, the access time is less than 3 seconds.

A new world record!

No one else can do it: the highest storage density with direct access. This is because the Servus-Lifter moves exclusively on the uppermost travel level.

The merging of warehouse and production

A single solution for the storage and supply of material

Modularly expandable

The basic model is possible from 3 m² and can be extended modularly in steps of 1 m². It can be extended in length as desired and up to a height of 6 m.

100% process reliable

All data on stock changes and transactions are available directly and in real time through intelligent camera monitoring.

User friendly and innovative

All processes can be displayed and controlled via smartphone or tablet using the Servus app.

Flexible for every connection

Perfect as a stand-alone solution or as a fully automatic connection within incoming and outgoing goods, with AGVs or the Servus Intralogistics System.

In service around the clock

24/7 material and parcel delivery, and collection via the integrated Servus Checkpoint.

The all-rounder for every use

Whether as a warehouse or decentralised buffer with connection to assembly stations, Kanban shelves, and automatic supermarkets.

At the right place, at the right time

Unobstructed material flow just-in-time down to the last "metre". In a one-piece-flow from the buffer directly to the assembly station.

All information for download

You can download the brochure with all the information in detail here.

Any questions?

Please feel free to contact us.

Servus Intralogistics GmbH

Dr. Walter Zumtobel Straße 2

A-6850 Dornbirn – Österreich

T +43 5572 22000 – 300

F +43 5572 22000 – 9300